Professional Mold Design: Services in Houston

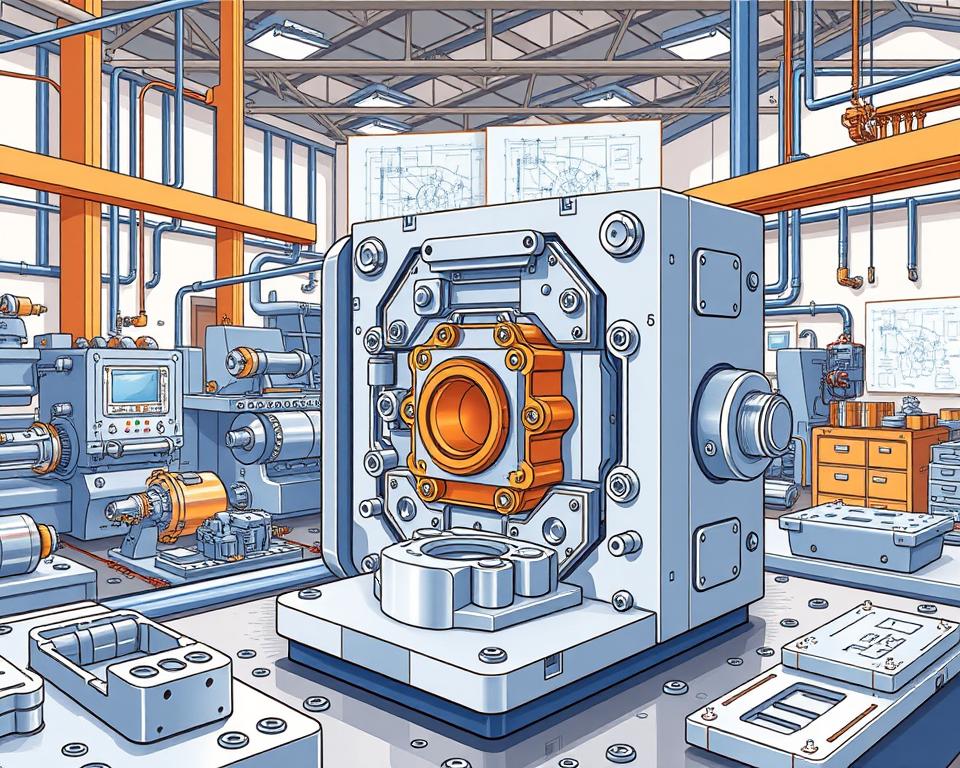

It’s projected that the global injection molded plastics industry will swell to $440 billion by 2025. This growth underlines the importance of professional mold design services. They deliver bespoke, top-tier mold designs across multiple sectors. In Houston, Lowrance Machine is a leading mold design company. They provide cutting-edge mold solutions for the automotive, aerospace, and consumer-goods markets.

Leveraging CAD platforms and 3D-printing technology, Lowrance Machine. Their experts guarantee both accuracy and speed throughout molding. Backed by deep expertise and technical know-how, they remain a trusted business ally. Discover how their mold design Houston offerings improve project outcomes and satisfy current market needs.

Understanding the Importance of Mold Design Services

Quality and efficiency in manufacturing hinge on expert mold design services. Mold design dictates product performance and durability. Companies that invest in expert mold design can cut production costs and improve quality standards.

Seasoned professionals at Lowrance Machine illustrate the benefits of expertise. They dive deep into client needs and work hand-in-hand to craft custom solutions. Through CAD-driven 3D modeling, they produce molds of exceptional standard.

Opting for premier mold design services elevates product functionality and powers business growth. Streamlined mold design fosters efficient production and sharpens competitive stance.

Available Mold Design Services in Houston

Lowrance Machine offers a wide range of mold design Houston services, tailored to meet specific industry needs. Knowing the different types of mold services helps businesses choose the best for their projects. Key categories include:

- Design Services: Personalized mold design services built around specific demands.

- Prototyping: Early-stage mold prototyping to validate designs.

- Injection Mold Fabrication: Precision-engineered injection molds built to last.

- 3D CAD Modeling: Advanced CAD to develop exact 3D mold prototypes.

- Repair and Maintenance: Repair and upkeep solutions to maximize mold longevity.

Each service is designed to streamline production, improve product quality, and ensure cost-efficiency. With clarity on service options, businesses can align mold solutions with their production goals.

Benefits of Choosing Professional Mold Design Experts

Choosing professional mold design experts brings numerous advantages to manufacturing processes. These benefits include enhanced accuracy, durability, and efficiency. Customized mold solutions tailored to specific needs lead to higher product quality and consistent results.

Seasoned teams provide critical workflow enhancements. They certify molds comply with both generic and custom criteria. Working together drives creative solutions and lengthens product durability.

Cost-effectiveness is a significant benefit. Modern techniques curb scrap and shorten lead times. Such efficiencies translate into meaningful cost reductions. Swift design workflows speed time-to-market, sharpening competitive positioning.

In summary, specialized mold design companies provide critical support for manufacturers. They focus on boosting throughput and product excellence.

Innovative Techniques in Mold Design

Innovation has driven monumental shifts in mold design. At the forefront, Lowrance Machine applies state-of-the-art methods. Such breakthroughs accelerate production and raise standards. Modern engineering tools expedite custom mold fabrication and lower overheads.

Additive manufacturing shines by producing fast prototypes and intricate shapes. It slashes raw-material loss relative to traditional processes. Simulation platforms enable virtual mold testing and enhancement for superior performance and throughput.

Locally, mold designers in Houston leverage these advanced practices. Firms achieve market edge through digital design and high-tech manufacturing. They facilitate flexible, rapid-response mold development to satisfy diverse applications.

| Technique | Description | Benefits |

|---|---|---|

| Additive Manufacturing | Utilizes additive manufacturing to create molds rapidly. | Shortens delivery times and cuts scrap. |

| Virtual Testing Tools | Visualizes mold design through computer models. | Enhances accuracy and optimizes performance. |

| CAD Platforms | Utilizes CAD/CAM for exact design work. | Facilitates customization and adaptation. |

To Summarize

Expert mold design is essential for streamlined production and superior output in Houston. These services bring specialized know-how to overcome mold design hurdles. They tailor solutions to individual requirements for optimal results.

As a leader in accuracy and client partnership, Lowrance Machine stands out. Custom designs and modern tools offered by these experts keep producers competitive. Working with mold design experts improves product quality and streamlines operations.

Choosing expert mold design services in Houston prioritizes both excellence and speed. Firms can deliver on client needs while improving their market position. Embracing these expert offerings is key to thriving in a challenging marketplace.