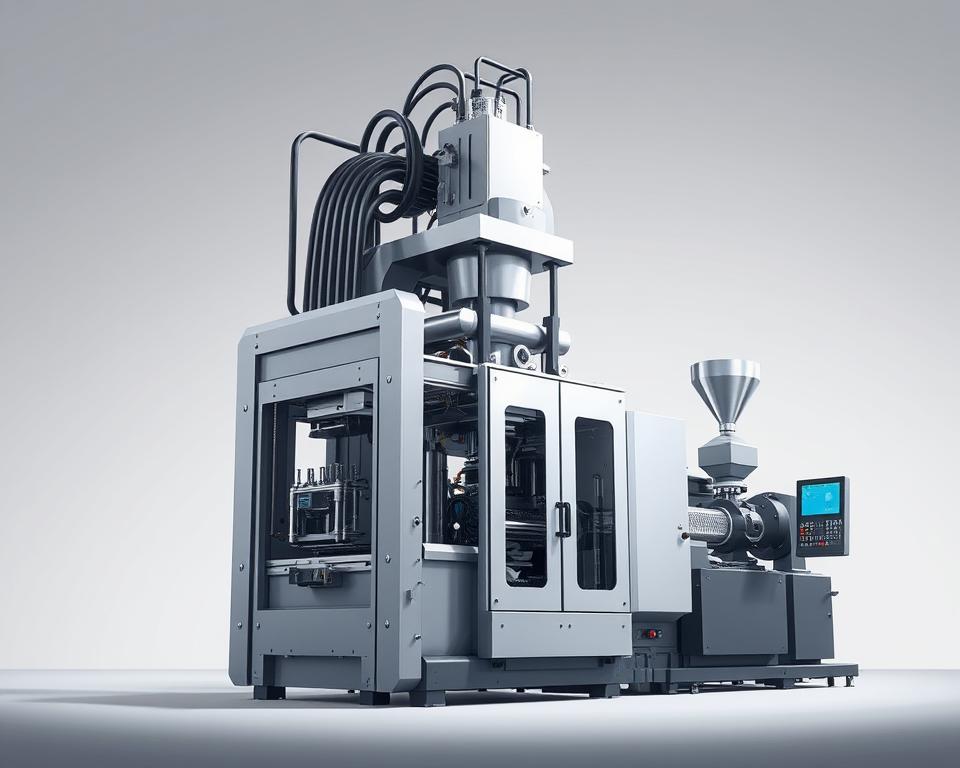

Best Practices for Sourcing Injection Molding from China

The important meeting has recently finished, your new product is a go, the schedule is tight, and the budget is, let’s say, constrained.. Then a voice—perhaps your manager or the CFO—drops the line that gives every project manager a shock: “We should look at sourcing this from China.”

Naturally, you agree. On paper, it’s logical. The cost savings can be huge. Yet your thoughts are already spinning. You know the rumors, don’t you? The quality disasters, the communication black holes, the shipment that shows up three months late looking nothing like the sample. It’s like balancing on a tightrope between a massive cost advantage and project disaster.

But here’s the catch. Sourcing China injection molding can be a calculated project. It’s no different from any structured project. And its outcome hinges on the approach you take. It’s not just about the lowest bid but selecting the best partner and overseeing every step. Forget the horror stories. Let’s go through a step-by-step guide to succeed.

Step One: Do Your Homework

Before searching suppliers or opening Alibaba, nail down your requirements. Truthfully, over fifty percent of offshore sourcing issues originate in an unclear project brief. You cannot expect overseas partners to interpret your unspoken requirements. A vague RFQ is like telling a contractor to bid on “a house.” The responses you get will be all over the map, and none of them will be useful.

Your RFQ should be bulletproof—clear, detailed, and unambiguous. This becomes the bedrock of your sourcing project.

What belongs in your RFQ?

First, your 3D CAD files. These are non-negotiable. Stick to universal formats like STEP or IGS to avoid any compatibility headaches. This is the authoritative CAD geometry.

Yet 3D models don’t cover everything. Include precise 2D engineering drawings. This details critical info missing from the 3D file. Examples include tolerances (e.g., ‘25.00±0.05 mm’), material grade, surface finish requirements, and functional callouts. Call out smooth surfaces or precision hole sizes in big, bold notation.

Then specify the material. Don’t label it simply “Plastic.” Don’t even just say “ABS.” Get precise. If you need SABIC Cycolac MG38 in black, say exactly that. Why so detailed? Because resin grades number in the thousands. Defining the exact material guarantees the performance and appearance you designed with what is plastic mold.

A good supplier can suggest alternatives, but you need to give them a clear starting point.

Finally, include the business details. What is your Estimated Annual Usage (EAU)? They need clarity: is it 1,000 total shots or a million units per annum? The tool design, the number of cavities, and the price per part all hinge on this number.

The Great Supplier Hunt

Okay, your RFQ package is a work of art. who gets your RFQ? The web is vast but overwhelming. Locating vendors is easy; vetting them is the real challenge.

You’ll probably kick off on Alibaba or Made-in-China. They offer breadth but not depth. But think of them as a starting point, not the finish line. Narrow your pool to about a dozen promising firms.

Still, you must dig deeper. Consider using a sourcing agent. Yes, they take a cut. But a good one has a vetted network of factories they trust. They bridge language and cultural gaps. As a newcomer, this offers priceless security. It’s schedule protection.

Also consider trade fairs. If you have the travel budget, attending a major industry event like Chinaplas can be a game-changer. Nothing beats a face-to-face conversation. You can handle sample parts, meet the engineers, and get a gut feeling for a company in a way that emails just can’t match. Plus, ask peers for referrals. Consult trusted colleagues. A solid referral can be more valuable than any ad.

Separating Real Suppliers from Pretenders

With your RFQ dispatched to dozens of firms, the quotes will start trickling in. You’ll see ridiculously low offers and steep quotes. Your job now is to vet these companies and narrow it down to two or three serious contenders.

How do you do that? It involves both metrics and gut feel.

Step one: audit communication. Do they respond quickly and clearly? Do they communicate effectively in English? The true litmus: are they raising smart queries? A great supplier will review your RFQ and come back with thoughts. Example: “Should we add draft here for better ejection?” or “Your tolerance may require extended CMM time—okay?” Consider that a big green light. You know they know their stuff. Anyone who simply agrees to all specs is a red flag.

Afterward, verify their technical arsenal. Get their tooling inventory. More importantly, ask for case studies of parts they’ve made that are similar to yours in size, complexity, or material. If you’re making a large, complex housing, you don’t want a shop that specializes in tiny gears.

Then comes the audit. This is not optional. Just as you interview hires, audit suppliers. You can either go yourself or, more practically, hire a third-party auditing firm in China to do it for you. They dispatch an on-site auditor for a day. They authenticate the firm, review ISO credentials, evaluate machines, and survey operations. It’s a tiny cost for huge peace of mind.

From Digital File to Physical Part

After picking your vendor, you’ve negotiated the price and payment terms—a common structure is 50% of the tooling cost upfront to begin work, and the final 50% after you approve the first samples. Now the real fun begins.

The first thing you should get back after sending your payment is a DFM report. Design for Manufacturability (DFM) is essential. It’s the engineering critique for moldability. The report calls out sink-risk zones, stress-causing corners, and draft angle gaps. Comprehensive DFM equals a top-tier supplier. It’s a collaboration. You work with their engineers to refine the design for optimal production.

With DFM sign-off, toolmaking begins. In a few weeks, you’ll see “T1 samples are on the way.” These represent the first trial parts. It’s your test of success.

T1 parts usually require adjustments. This is normal! Look for small flaws, slight size errors, or surface marks. You critique, they refine, and T2 plastic mold in China parts arrive. This process might take a couple of rounds. The key for you, as the project manager, is to have this iteration loop built into your timeline from the start.

At last, you get the perfect shot. It matches all specs, has a pristine finish, and works as required. This is now the benchmark sample. You formally approve it, and this sample is now the standard against which all future mass-produced parts will be judged.

Crossing the Finish Line

Getting that golden sample feels like the end, but it isn’t. Now comes full-scale production. How do you maintain consistency for part 10,000?

Implement a robust QC plan. Typically, this means a pre-shipment audit. Again, you can hire a third-party service. For a few hundred dollars, they will go to the factory, randomly pull a statistically significant number of parts from your finished production run, and inspect them against your 2D drawing and the golden sample. You receive a full report with images and measurements. Only after you approve this report do you authorize the shipment and send the final payment. This step saves you from a container of rejects.

Don’t forget shipping details. Understand the shipping terms, or Incoterms. Is your price FOB (Free On Board), meaning the supplier’s responsibility ends when the goods are loaded onto the ship in China? Or EXW, where you handle everything from their gate? These details have a big impact on your final landed cost.

Overseas sourcing is a marathon. It hinges on strong supplier relations. See them as collaborators, not vendors. Open dialogue, trust, and rigorous procedure deliver results. It’s a challenging project, no doubt. However, armed with this guide, you’ll secure savings and keep high standards intact. You’re ready.